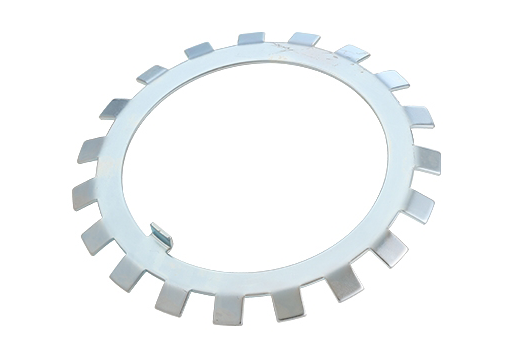

Prevailing Torque Bearing Nut With Metal Insert/GUK NUT

Prevailing Torque Bearing Nut With Metal Insert: No washer needed

The Prevailing Torque Bearing Nut With Metal Insert is a type of lock nut that features a prevailing torque to assist in preventing self-loosening. The metal prevailing torque locknuts get the feature of prevailing torque when the threads are distorted at the top of the nut.

The prevailing torque in the locknuts works on three variations such as localized plastic deformation, interference fit, and continuous sliding. In localized plastic deformation, some of the starting threads of the nut need to meet the mating part before the prevailing torque process begins. In the case of all-metal locknuts, these threads are deflected plastically so that there are different points of interference with the threads of the mating part.

In interference fit, the threads of prevailing torque lock nut have negative clearance. This means neither there is contact nor deflection with the mating part. In continuous sliding, when the nut is installed the thread surfaces of the locknut and bolt come in contact as they slide across each other.

When high temperatures, high torque, high vibration, corrosion, and tensile strength are involved in any process, industries rely on all metal prevailing torque nuts.

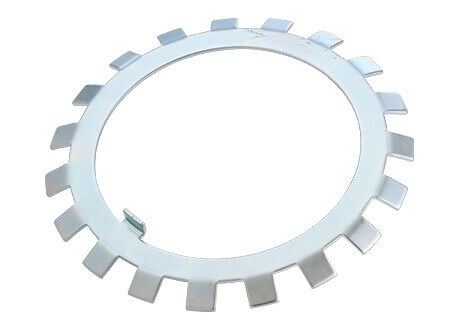

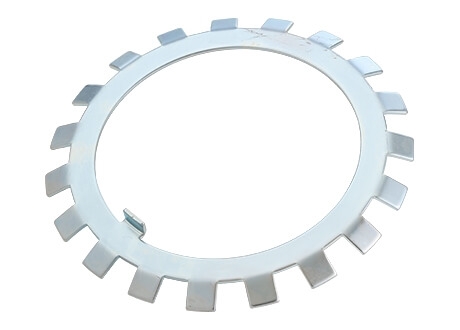

GUK Self-Locking Nuts: No washer needed

A self-locking nut is a nut that resists loosening under vibrations and torque. Elastic stop nuts and prevailing torque nuts are of the particular type where some portions of the nut deform elastically to provide a locking action.

Their locking action is created by the distortion of their uppermost threads and should resist loosening caused by shock, vibration, and other forces. They host a self-contained feature which creates frictional interference between the threads of mating components.

Safety lock nuts are reusable with a limited number of times as the prevailing torque declines each time the nut is used. The self-locking nut offers an easier and more cost-effective solution to protect against vibration-related loosening. Using just one lock nut, manufacturing companies can secure multiple objects together without fear of vibrations loosening the nut. Even under heavy vibrations, they will remain stable and secure to the bolt on which they are used.

The special shape of the thread of the safety lock nut effectively prevents failure and at the same time reuses the nut. Also, the number of components is reduced by the self-assurance of the base, since no further security elements are needed. The screw lock counteracts the unintentional release, without the need to process the screw itself.

.png)

-index.jpg)

_防鬆螺帽-1.jpg)