Ball Screw FSE / FSB

Product Introduction

| Variation per 300mm(e300) (JIS B 1192) / Unit: mm | |||||||

|---|---|---|---|---|---|---|---|

| Grade | C0 | C1 | C2 | C3 | C5 | C7 | C10 |

| e300 | 0.0035 | 0.005 | 0.007 | 0.008 | 0.018 | 0.05 | 0.21 |

Selection of Nut:

- Series: When making selection of series, please take into consideration of demanded accuracy, dimensions, and preload, etc.

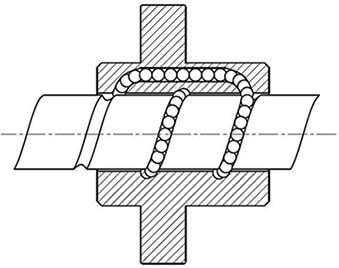

- Circulation type:

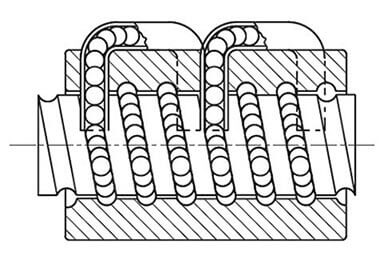

(a) External circulation type- Economy

- Suitable for mass production

- Applicable to those with larger lead or larger outside diameter of screw shaft

- With nuts of finely crafted outside diameter (occupying small space)

- Applicable to those with small lead or small outside diameter of the screw

- High Speed, High DN Value

- Low noise, Green product

- Small Size, Space saving

- Number of loop circuits: Performance and life service should be considered when selecting number of loop circuits.

- Shape of flanges: Please make selection based on the available space for the installation of nuts.

- Oil hole: Oil holes are provided for the precision Ball Screws, it can be used during machine assembling and regular maintenance.

External ball circulation nuts:

*Feature:

*Feature:

1.Provide smoother ball running

2.Provides better quality for long lead or large diameter of ball screws

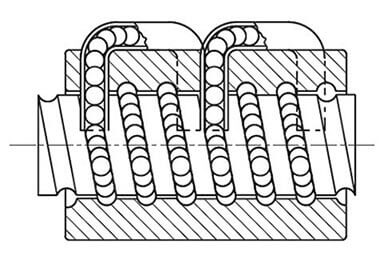

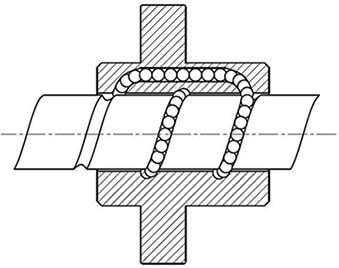

Internal ball circulation nuts:

*Feature:

*Feature:

It is suitable for the machine with limit space for Ball Screw installation. And it is strictly required the screw shaft must contain min one end with complete threads. In order to assemble successfully, the rest area next to this complete thread must be with smaller diameter than the nominal diameter of the screw shaft.

High lead ball screw:

*Feature:

*Feature:

- High DN value

- The DN value can be 130,000 in normal case. For some special cases, for example, in a fixed ends case, the DN value can be as high as 140,000.

- High speed

- High speed ball screws provide 100 m/min and even higher speed for machine tools.

- High rigidity

- Screw shaft and nut are both surface hardened to a specific hardness and case depth to maintain high rigidity and durability.

- Multiple thread starts are available to make more steel balls loaded in the nut for higher rigidity and durability.

- Low noise

- Special design of ball circulation tubes which provide smooth ball circulation inside the nut. It also makes steel ball running into the tubes without damaging the tubes.

- Accurate ball circle diameter through whole threads for consistent drag torque and low noise.

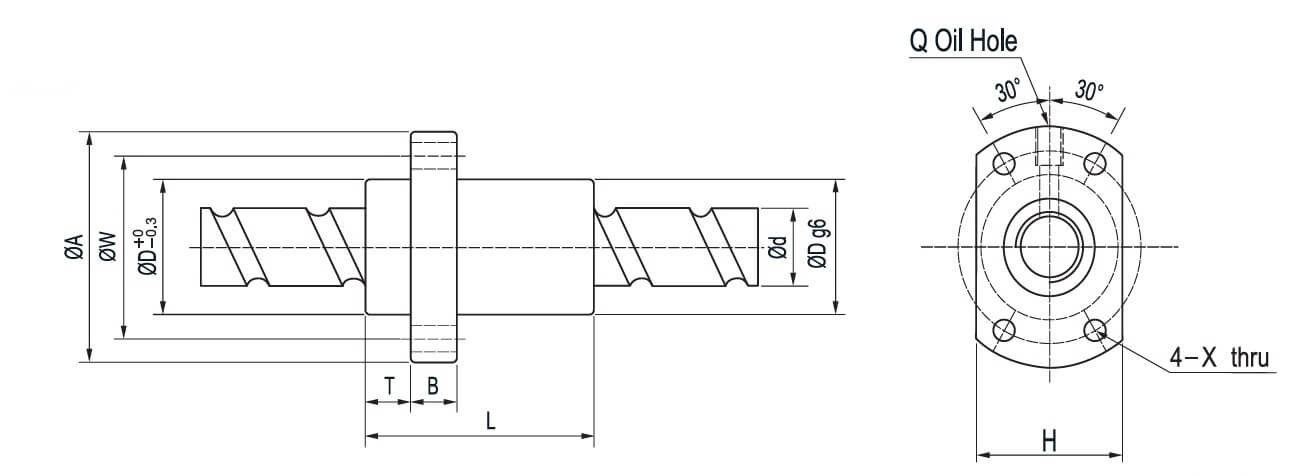

Product Model : FSE

| Model No. | Dimension | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| d | I | Da | D | A | B | T | L | W | X | H | Q | n | Ca(Kgf) | Coa(kgf) | |||

| 1616-2 | 16 | 16 | 3.175 | 32 | 53 | 10 | 10.5 | 48 | 42 | 4.5 | 38 | M6 | A2 | 1512 | 1995 | ||

| ★2020-2 | 20 | 20 | 3.175 | 39 | 62 | 10 | 10.8 | 55 | 50 | 5.5 | 46 | M6 | A2 | 1659 | 2464 | ||

| 2520-2 | 25 | 20 | 3.5 | 47 | 74 | 12 | 11 | 65 | 60 | 6.6 | 49 | M6 | A2 | 2106 | 3422 | ||

| 2525-2 | 25 | 25 | 3.969 | 47 | 74 | 12 | 11.2 | 67 | 60 | 6.6 | 56 | M6 | A2 | 2481 | 3851 | ||

| 3232-2 | 32 | 32 | 4.762 | 58 | 92 | 15 | 14 | 82 | 74 | 9 | 68 | M6 | A2 | 3585 | 6071 | ||

| 4040-2 | 40 | 40 | 6.35 | 73 | 114 | 17 | 17 | 100 | 93 | 11 | 84 | M6 | A2 | 5778 | 11753 | ||

| 5050-2 | 50 | 50 | 7.938 | 90 | 135 | 20 | 21.5 | 125 | 112 | 14 | 92 | M6 | A2 | 8819 | 19241 | ||

|

★Can be produced left-hand thread

|

|||||||||||||||||

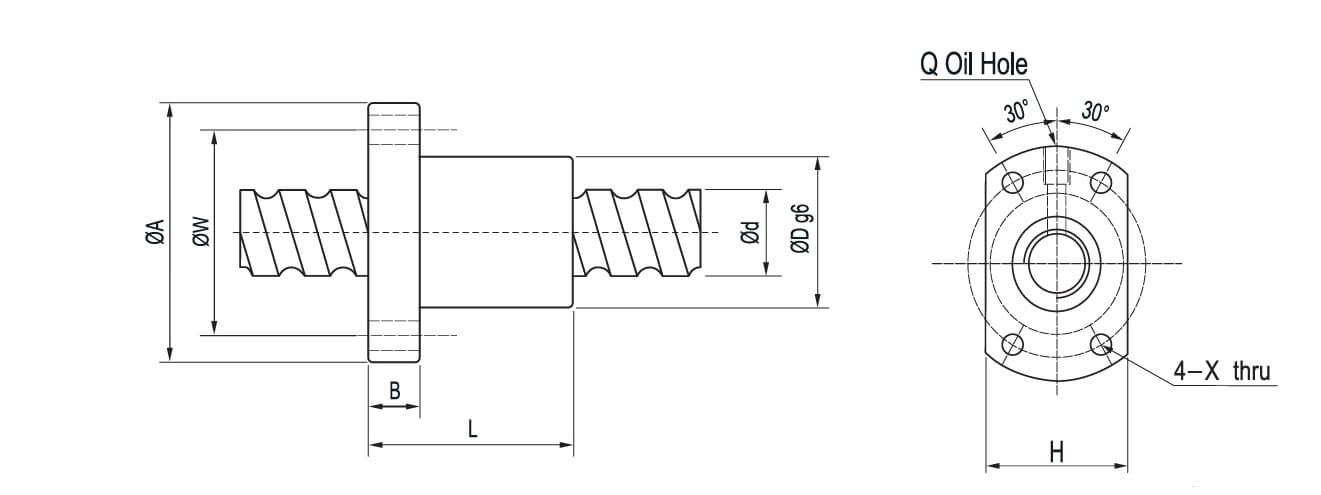

Product Model : FSB

| Model No. | Dimension | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| d | I | Da | D | A | B | L | W | X | H | Q | n | Ca(Kgf) | Coa(kgf) | |

| 1404-3 | 14 | 4 | 2.381 | 31 | 50 | 10 | 40 | 40 | 4.5 | 37 | M6 | T3 | 684 | 792 |

| 1405-3 | 14 | 5 | 3.175 | 32 | 50 | 10 | 45 | 40 | 4.5 | 38 | M6 | T3 | 1013 | 1056 |

| 1605-3 | 16 | 5 | 3.175 | 34 | 54 | 10 | 42 | 44 | 4.5 | 40 | M6 | T3 | 1049 | 1144 |

| 2005-3 | 20 | 5 | 3.175 | 40 | 60 | 10 | 47 | 50 | 4.5 | 46 | M6 | T3 | 1181 | 1496 |

| 2505-3 | 25 | 5 | 3.175 | 43 | 67 | 10 | 47 | 55 | 5.5 | 50 | M6 | T3 | 1330 | 1936 |

| 2510-3 | 25 | 10 | 4.762 | 60 | 96 | 15 | 75 | 78 | 9 | 72 | M6 | T3 | 2250 | 2772 |

| 2510-4 | 25 | 10 | 4.762 | 60 | 96 | 15 | 97 | 78 | 9 | 72 | M6 | T4 | 2881 | 3695 |

| 3210-3 | 32 | 10 | 6.35 | 67 | 103 | 15 | 78 | 85 | 9 | 78 | M6 | T3 | 3775 | 5877 |

| 3210-4 | 32 | 10 | 6.35 | 67 | 103 | 15 | 97 | 85 | 9 | 78 | M6 | T4 | 4834 | 7835 |

| 4010-4 | 40 | 10 | 6.35 | 76 | 116 | 17 | 100 | 96 | 11 | 88 | M6 | T4 | 5399 | 10074 |

.png)

-index.jpg)

_防鬆螺帽-1.jpg)