Self-lubricated Bushings SPW

Product Introduction

Material: High Tensile Brass Alloy + Graphite Solid Lubricant Embedded

Features:- May work without any oil for a long period.

- Extremely high load capacity, good anti-wear and lower friction

- Particularly appropriate for low speed and high load.

- Suitable for reciprocating, oscillating or intermittent motion where oil film is hard to be formed.

- Good chemical resistant and anti-corrosion characteristics.

- Can be used in wide range of temperature from -40℃-+300℃.

- Low maintenance frequency.

| Technical Data | |

|---|---|

| Material | CuZn24AL6 |

| Hardness | HB230-270 |

| Coefficient of friction(μ) | <0.16 |

| Max. Temp. | 300℃ |

| Max. dynamic load | 100 N/mm² |

| Max. speed(Dry) | 0.4 m/s |

| Max. speed (Lubrication) | 5 m/s |

| PV limit | 3.8 N/mm² *m/s |

| Chemical Compositions | ||||||||

|---|---|---|---|---|---|---|---|---|

| Chemical Compositions % | ||||||||

| Cu | Zn | Al | Fe | Mn | Si | Ni | Sn | Pb |

| 64.24 | 25.10 | 5.17 | 2.67 | 2.82 | <0.1 | <0.5 | <0.2 | <0.2 |

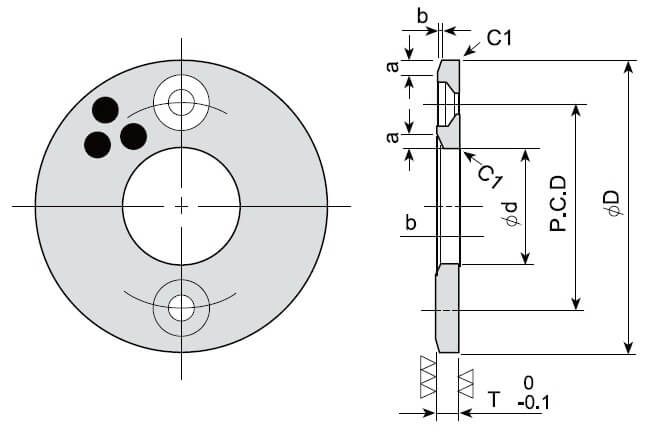

Product Model : SPW

- Self-lubricated Bushings #500SP.

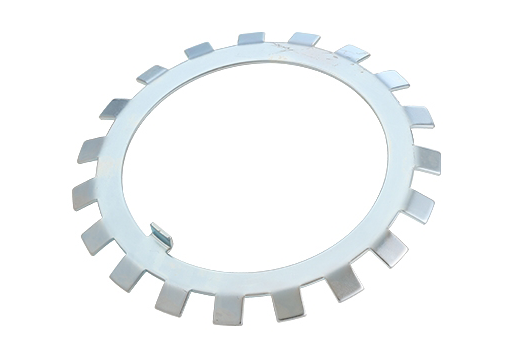

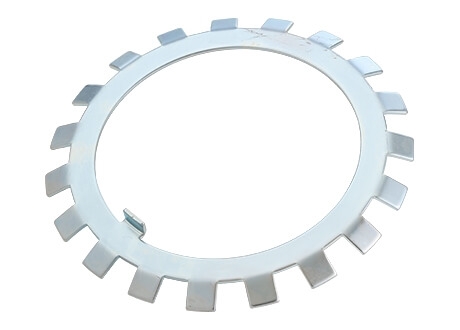

- Thrust Washers (SPW)

*Please refer to SPB configuration

*Can be combined with SPB product

| ITEM NO=SPW-XX XX | ||

| ID Thickness | ||

| Dimension (mm) | Thickness (Tolerance  ) ) | Mounting hole | Chamfer | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | OD | 3 | 5 | 7 | 8 | 10 | |||||

| Ød | ØD | SPW | SPW | SPW | SPW | SPW | P.C.D | Q'ty | countersunk bolt screw | a | b |

| 10.2 | 30 | -1003 | 20 | 2 | M3 | 1.5 | 0.3 | ||||

| 12.2 | 40 | -1203 | 28 | 2 | M3 | 2 | 0.4 | ||||

| 12.2 | 40 | -1203N | no countersunk bolt hole | 2 | 0.4 | ||||||

| 13.2 | 40 | -1303 | 28 | 2 | M3 | 2 | 0.4 | ||||

| 14.2 | 40 | -1403 | 28 | 2 | M3 | 2 | 0.4 | ||||

| 15.2 | 50 | -1503 | 35 | 2 | M3 | 2 | 0.4 | ||||

| 16.2 | 50 | -1603 | 35 | 2 | M3 | 2 | 0.4 | ||||

| 16.2 | 50 | -1603N | no countersunk bolt hole | 2 | 0.4 | ||||||

| 18.2 | 50 | -1803 | 35 | 2 | M3 | 2 | 0.4 | ||||

| 20.2 | 50 | -2005 | 35 | 2 | M5 | 2.5 | 0.4 | ||||

| 25.2 | 55 | -2505 | 40 | 2 | M5 | 2.5 | 0.4 | ||||

| 30.2 | 60 | -3005 | 45 | 2 | M5 | 2.5 | 0.4 | ||||

| 35.2 | 70 | -3505 | 50 | 2 | M5 | 2.5 | 0.4 | ||||

| 40.2 | 80 | -4007 | 60 | 2 | M6 | 3 | 0.5 | ||||

| 45.2 | 90 | -4507 | 70 | 2 | M6 | 3 | 0.5 | ||||

| 50.3 | 100 | -5008 | 75 | 4 | M6 | 4 | 0.6 | ||||

| 55.3 | 110 | -5508 | 85 | 4 | M6 | 4 | 0.6 | ||||

| 60.3 | 120 | -6008 | 90 | 4 | M8 | 5 | 0.8 | ||||

| 65.3 | 125 | -6508 | 95 | 4 | M8 | 5 | 0.8 | ||||

| 70.3 | 130 | -7010 | 100 | 4 | M8 | 5 | 0.8 | ||||

| 75.3 | 140 | -7510 | 110 | 4 | M8 | 5 | 0.8 | ||||

| 80.3 | 150 | -8010 | 120 | 4 | M8 | 5 | 0.8 | ||||

| 90.5 | 170 | -9010 | 140 | 4 | M10 | 5 | 0.8 | ||||

| 100.5 | 190 | -10010 | 160 | 4 | M10 | 5 | 0.8 | ||||

| 120.5 | 200 | -12010 | 175 | 4 | M10 | 5 | 0.8 | ||||

.png)

-index.jpg)

_防鬆螺帽-1.jpg)